At Sumpot we are always eager to push the limits of innovation and develop new sterilization equipment to solve our customers' needs. Standing behind all of our equipment is our team of seasoned professionals and advanced CAD tools. Sumpot is dedicated to making "Made in China" globally trusted, and we are working towards this goal.

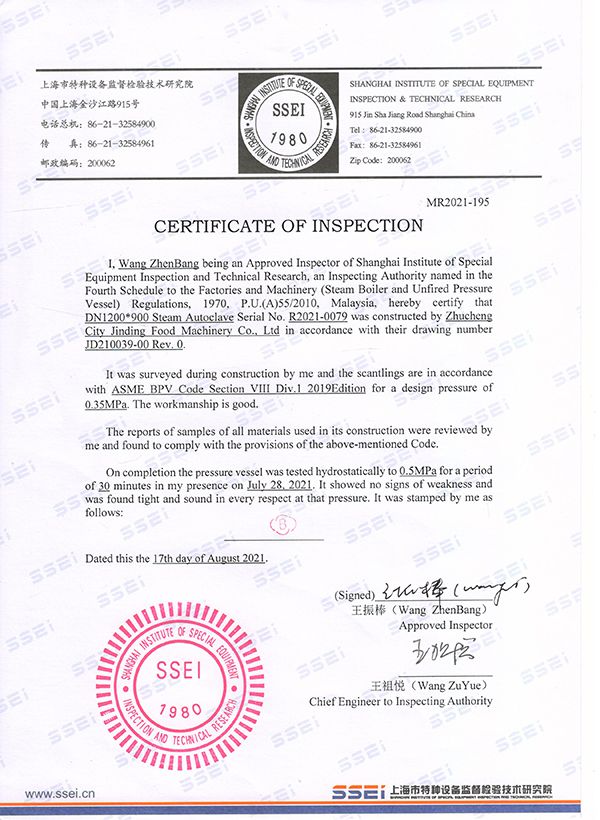

Sumpot's independently developed food retort sterilizers have obtained over 10 national patents and are CE compliant to successfully enter the European market. At our manufacturing plant, our team of more than 200 workers enables us large enough to meet the demands on today's industry and deliver products to every customer on time. Our monthly production capacity can reach 20 units.

We adopt reliable parts from world's trusted supplier such as Siemens, Mitsubishi and SMC to guarantee the high quality of our batch retorts.

First Step

First Step

Vessel fabrication Second Step

Second Step

Non-destructive testing Third Step

Third Step

Accessory welding Fourth Step

Fourth Step

Pipe shaping

Fifth Step

Fifth Step

Parts assembly Sixth Step

Sixth Step

Pressure testing Seventh Step

Seventh Step

Insulation layer forming Eighth Step

Eighth Step

Door assembly

Ninth Step

Ninth Step

Electrical installation Tenth Step

Tenth Step

Process testing Elevent Step

Elevent Step

Packing and delivery

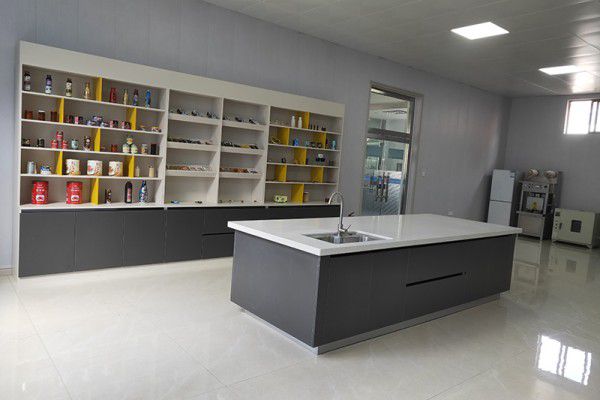

All our incoming raw materials are subjected to complete inspection and sample inspection to reject unqualified raw materials. Throughout the production process, every step is strictly controlled by designated personnel, preventing substandard products from entering the next process. We are focusing on our quality management system to continually improve our product quality and work efficiency, ultimately ensuring that our retort sterilizers meet the international standards, are delivered to customers on schedule, and we keep customers informed every step of the way.