Steam-Air Retort

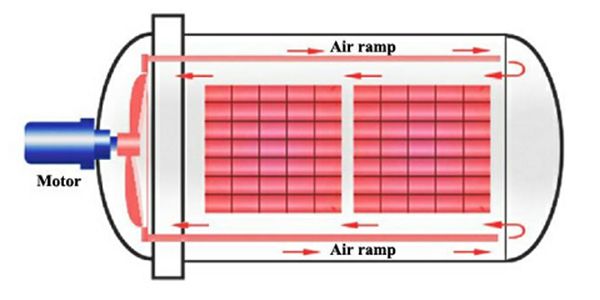

Steam-air retort is a batch type autoclave used for sterilizing food products packaged in nearly all types of cans. Two steam pipes are installed at the bottom of the batch retort to provide heat into the retort chamber, without exhausting process. A large-flow axial fan located inside of the retort is used as driving force to mix the steam with the air, and circulate the steam-air mixture that is used as heating medium to flow throughout the retort for uniform sterilizing of canned foods.

Request a Quote

Applications

Steam-air retort is suitable for sterilizing nearly all types of glass and metal cans (excluding sausage casings).

Specifications

| Model | Diameter (mm) | Length (mm) | Wall thickness (mm) | Capacity (m3) | Dimension (mm) | Max. working pressure (MPa) | Max. working temperature (°C) | Approx. retort weight (kg) | Approx. operating weight (kg) | Power (kW) | Voltage (V) | ||

| L | W | H | |||||||||||

QH10-2 | 1000 | 1800 | 4 | 1.65 | 3360 | 1470 | 1650 | 0.3 | 130 | 1560 | 2060 | 3 | 380 |

QH12-4 | 1200 | 3600 | 5 | 4.46 | 5460 | 1700 | 1850 | 0.3 | 130 | 1120 | 3560 | 5.5 | 380 |

QH14-4 | 1400 | 4000 | 6 | 6.77 | 5760 | 1900 | 2200 | 0.3 | 130 | 2760 | 4720 | 7.5 | 380 |

QH15-4 | 1500 | 4000 | 6 | 7.82 | 6260 | 2000 | 2400 | 0.3 | 130 | 3360 | 6160 | 11 | 380 |

QH15-5 | 1500 | 5000 | 6 | 9.59 | 7110 | 2000 | 2400 | 0.3 | 130 | 3510 | 6260 | 11 | 380 |

QH15-6 | 1500 | 6000 | 6 | 11.35 | 7960 | 2000 | 2400 | 0.3 | 130 | 3760 | 6960 | 11 | 380 |

Working Principle

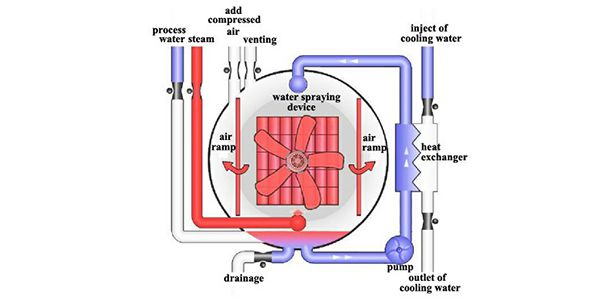

- Sterilization: The sterilization process begins by introducing steam into a steam-air retort. Inside the steam-air retort, there is a circulating fan that rapidly circulates the steam and air at a high speed. This circulation ensures that the temperature inside the retort is equally distributed throughout. Gradually, the temperature inside the retort is increased and adjusted to reach the desired temperature and pressure range. This adjustment is achieved using a pressure-adjusting valve and an exhaust valve. The pressure-adjusting valve controls the pressure, while the exhaust valve helps in reducing the pressure when necessary.

- Cooling: To create a closed system for sterilizing water, it is injected into the retort. The sterilizing water is then circulated within the closed system by a circulating pump. This circulation creates a mist that covers the surface of the sterilizer, ensuring effective sterilization. At this stage, the cooling process begins. Cooling water is introduced into a heat exchanger, which helps reduce the temperature of the circulating water gradually. The cooling continues until the desired temperature level is reached.

- Blowdown: The blowdown valve expels the remaining sterilization water, while the exhaust valve is used to reduce the pressure inside the retort.

Features

- Energy efficient, this steam-air retort can save approximately a quarter of the steam required in a conventional steam sterilizer. When comparing to water spray retort and water immersion retort, the steam-air retort eliminates the need for steam used for water heating because that it does not use hot water as heat transfer medium.

- Steam is produced from the boiler treatment using sterile water, and then leaves the boiler through piping to uniformly transfer heat to the retort chamber.

- Large-flow axial fan has a robust structure, providing long service life.

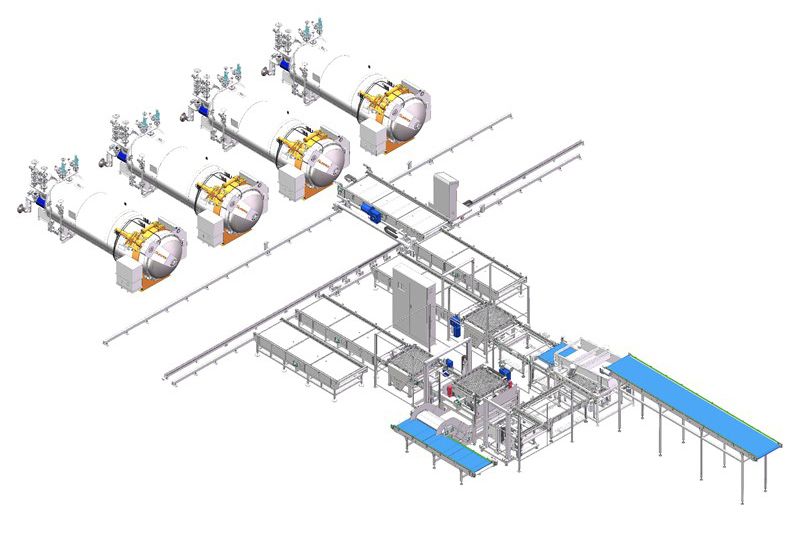

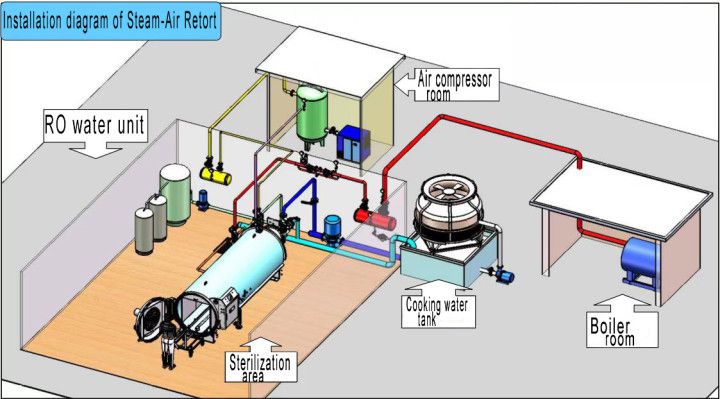

Installation Diagram

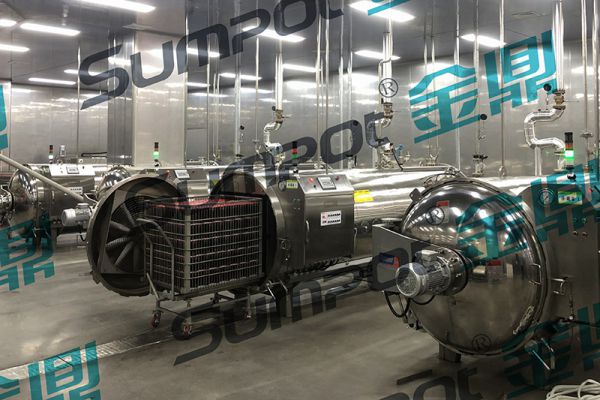

Steam-air retort operates at customer's site

FAQ

- This food sterilizer is designed for efficient steam and hot water usage, making it an energy-saving food sterilization equipment.

- It boasts flexible and precise controls for temperature and pressure.

- Integrated fans ensure even steam circulation within the retort, guaranteeing effective sterilization.

This retort offers versatile sterilization, suitable for rigid containers, flexible packaging, and can packaging, making it a multifaceted food sterilization machine.

The equipment is adept at handling:

- Fish and seafood

- Baby food

- Meat and sausage

- Ready-meals and soups

- Milk, cream, and beverages

- Vegetables and fruits

- Pet food

- ... and more.

This food sterilization machine finds wide applications in fruit and vegetable processing plants, beverage filling companies, seafood processing companies, baby food manufacturers, and others. It can be integrated effortlessly into diverse food processing lines.

Certainly. Beyond our existing food retorts, we engage in new product development and innovative design, tailored to client specifications, covering an expansive range of needs in retort processing in the realm of food tech.

Upon acquiring our food processing equipment, we facilitate equipment installation, sterile processing technician training, sterilization equipment calibration, and subsequent maintenance. For more details, please click here.

Get in Touch

As a Chinese manufacturer of food retorts and autoclaves, Sumpot has distributed food sterilization equipment to markets around the world. Since the day of our establishment, we have aimed at serving the food processing industry for sterilization of food products that people can enjoy with confidence. To uphold our commitment, we constantly strive to ensure our equipment is skillfully manufactured and carefully inspected. The reliable machine performance and excellent customer service are particularly appreciated by our customer worldwide. To date, we have served 1157 global customers, and the number is rising continuously…