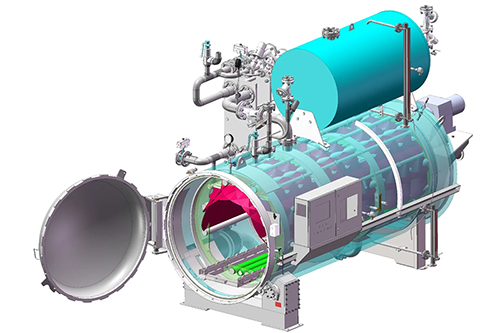

Water Spray Retort with Preheat Tank

If the product a customer is filling requires a temperature of at least 60 degrees, they should consider using a sterilization retort with a preheat tank. This will ensure the product is heated to the desired temperature.

The preheat tank is designed to heat sterilization water before it is fed into the upper tank. This ensures high efficiency and energy saving in the sterilization process and guarantees a successful outcome.

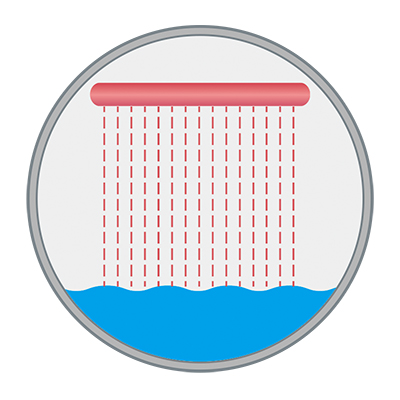

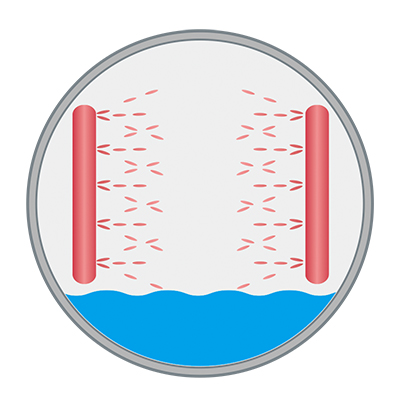

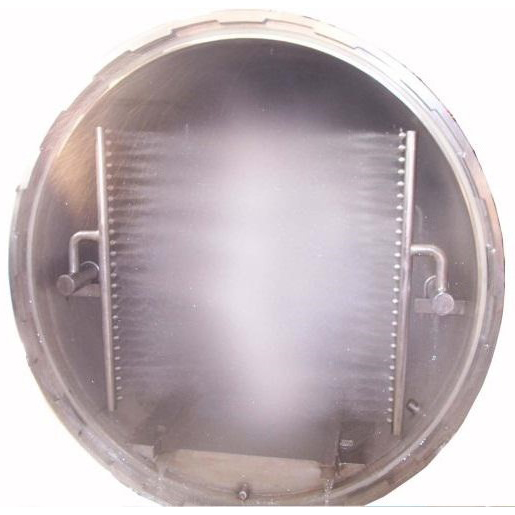

The water spray retort with a preheat tank offers three different spraying options: top+two sides spray, top spray and side spray. Of these, top+two sides spraying has been widely used in the past and is much more effective in terms of sterilization. It has also received higher customer acceptance than the other two types.

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (Mpa) | Max. working temperature (℃) | Approx. retort weight (kg) | Approx. operating weight (kg) | Power (kW) | Voltage (V) | ||||

| Capacity (m3) | ||||||||||||

| L | W | H | Top spray (water cascading) | Side spray / combined top and side spray | ||||||||

PLJ09-2 | 3080 | 1400 | 1400 | 4 | 0.3 | 130 | 1020 | 1500 | 1.33 | 3 | 4 | 380 |

PLJ10-1 | 2300 | 1500 | 1650 | 4 | 0.3 | 130 | 1000 | 1300 | 0.95 | 1.5 | 2.2 | 380 |

PLJ10-2 | 3100 | 1470 | 1650 | 4 | 0.3 | 130 | 1300 | 1800 | 1.65 | 3 | 5.5 | 380 |

PLJ12-2 | 3400 | 1700 | 1850 | 5 | 0.3 | 130 | 1380 | 2100 | 2.43 | 4 | 7.5 | 380 |

PLJ12-3 | 4300 | 1700 | 1850 | 5 | 0.3 | 130 | 1630 | 2750 | 3.46 | 4 | 7.5 | 380 |

PLJ12-4 | 5200 | 1700 | 1850 | 5 | 0.3 | 130 | 1860 | 3300 | 4.46 | 5.5 | 7.5 | 380 |

PLJ13-4 | 4600 | 1800 | 2100 | 6 | 0.3 | 130 | 2300 | 4000 | 5.81 | 7.5 | 11 | 380 |

PLJ14-4 | 5500 | 1900 | 2200 | 6 | 0.3 | 130 | 2500 | 4460 | 6.77 | 7.5 | 11 | 380 |

PLJ15-4 | 5800 | 2000 | 2400 | 6 | 0.3 | 130 | 2900 | 5900 | 7.82 | 11 | 15 | 380 |

PLJ15-5 | 6850 | 2000 | 2400 | 6 | 0.3 | 130 | 3250 | 6000 | 9.59 | 11 | 15 | 380 |

PLJ15-6 | 7700 | 2000 | 2400 | 6 | 0.3 | 130 | 3500 | 6700 | 11.35 | 11 | 15 | 380 |

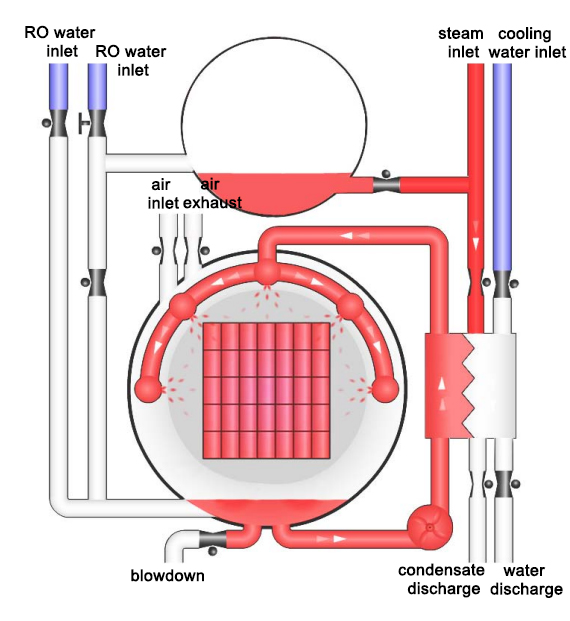

- Injecting and Preheating Sterilized Water: A specified quantity of sterilization water is injected into the preheater. The preheater prepares the water for the sterilization process by bringing it to the desired temperature before entering the main system.

- Sterilization: The sterilization process begins with the injection of sterilization water from a preheat tank. A circulating pump continuously moves this water through a closed system. As the water circulates, it vaporizes into steam and is sprayed onto the surface of the product. Steam is introduced to the heat exchanger, raising the temperature. The temperature is regulated to a predetermined amount, and the pressure in the retort is controlled within the desired range.

- Cooling and Recirculation: First, the steam entering the heat exchanger is stopped. Cooling water is then introduced into the exchanger to lower the temperature of the circulating water to around 80℃. The sterilizing water from the sterilization retort is recycled back to the preheating tank. The sterilization process is repeated by circulating the sterilizing water through the closed system using a circulating pump. The temperature is gradually reduced to a set level, ensuring that the products are cooled and safe to handle.

- Blowdown and Drainage: The steam pressure in the vessel is released through the exhaust valve. After the pressure is released, the remaining sterilization water is allowed to flow out through the drain valve.

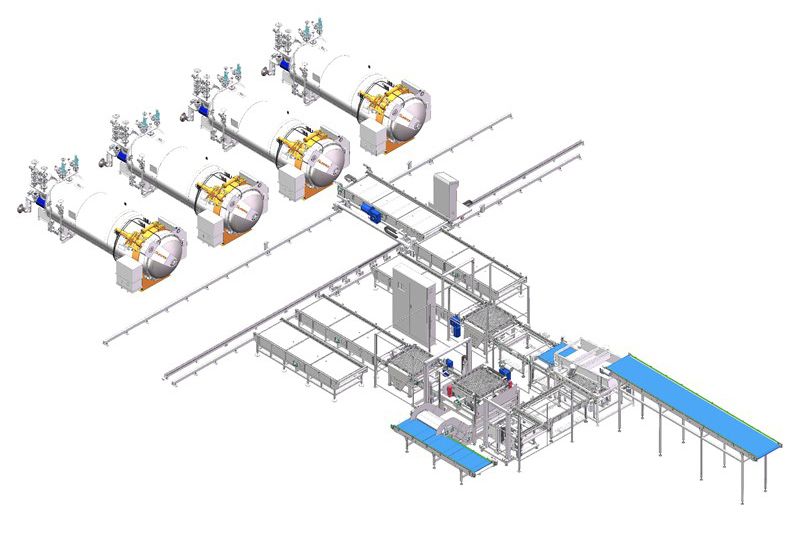

The retort sterilization equipment provides three distinct sterilization methods to cater to various retort food processing needs:

- Top spray retort

- Top + two sides spray retort

- Side spray retort