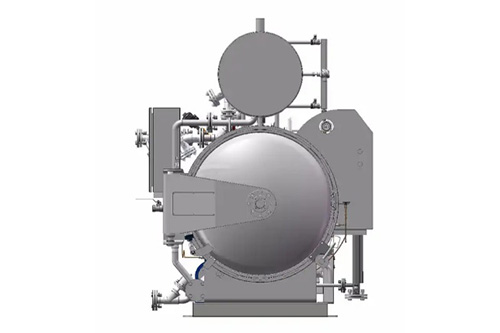

Water Spray Retort with Preheat Tank (with Electric Heating)

Water spray retort with preheat tank is suitable for situations where the steam is not available, utilizing electric heating as a substitute for steam heating.

Request a Quote

Specifications

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (Mpa) | Max. working temperature (℃) | Approx. retort weight (kg) | Approx. operating weight (kg) | Power (kW) | Voltage (V) | ||||

| Capacity (m3) | ||||||||||||

| L | W | H | Top spray (water cascading) | Side spray / combined top and side spray | ||||||||

PLJ09-2 | 3080 | 1400 | 1400 | 4 | 0.3 | 130 | 1020 | 1500 | 1.33 | 3 | 4 | 380 |

Working Principle

- Water Injection: Fill the preheat tank with an appropriate amount of sterilized water and activate the electric heating tube to preheat the water to the set temperature.

- Sterilization: To transfer the sterilized water from the preheat tank to the sterilization retort, a circulation pump is used to continuously circulate the water in a closed-loop system. The water mist is sprayed onto the surface of the sterilized material. With the heating of the electric heating tube, the temperature of the circulating water gradually rises and is ultimately controlled at the desired temperature. The pressure inside the retort is adjusted within the ideal range through pressure valves and steam vent valves.

- Cooling: External cooling water is run on the outside of the heat exchanger to cool the water inside of the retort, which lowers the temperature of the circulating water to around 80°C. The sterilized water in the retort is recovered back to the preheat tank, and then the new sterilized water is injected into the retort again. The circulation pump continuously circulates the sterilized water in the closed-loop system while cooling it to the set temperature.

- Drain: The remaining sterilized water is discharged through the drain valve, and the pressure inside the retort is released through the vent valve.

Get in Touch

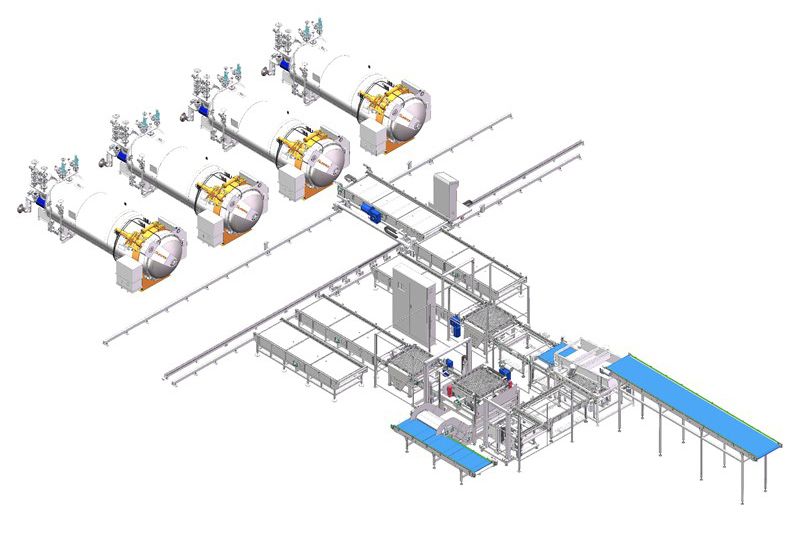

As a Chinese manufacturer of food retorts and autoclaves, Sumpot has distributed food sterilization equipment to markets around the world. Since the day of our establishment, we have aimed at serving the food processing industry for sterilization of food products that people can enjoy with confidence. To uphold our commitment, we constantly strive to ensure our equipment is skillfully manufactured and carefully inspected. The reliable machine performance and excellent customer service are particularly appreciated by our customer worldwide. To date, we have served 1157 global customers, and the number is rising continuously…