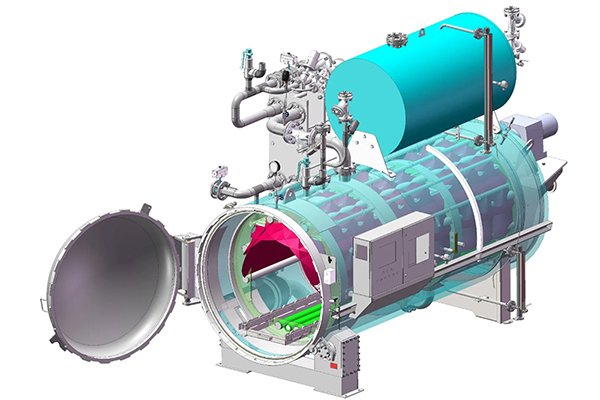

Static Water Spray Retort

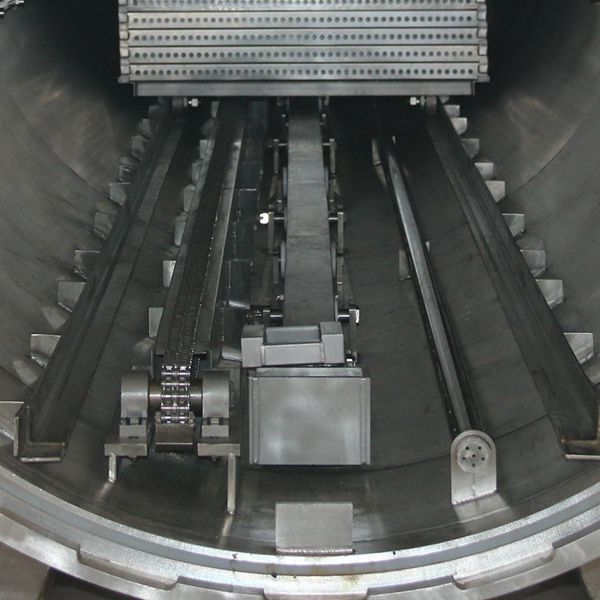

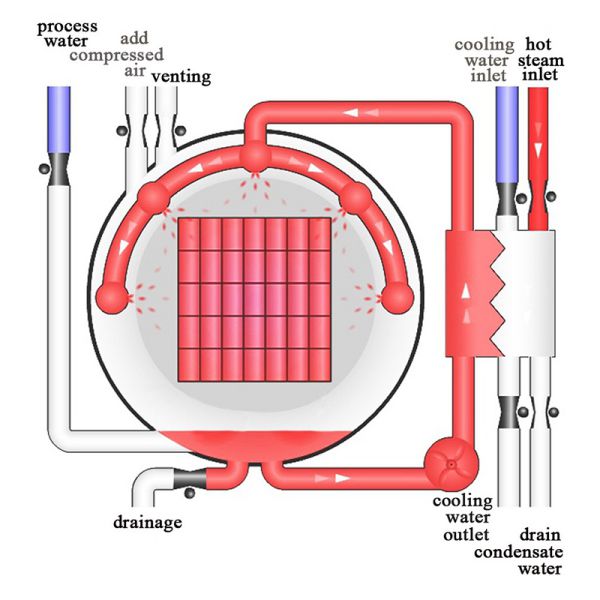

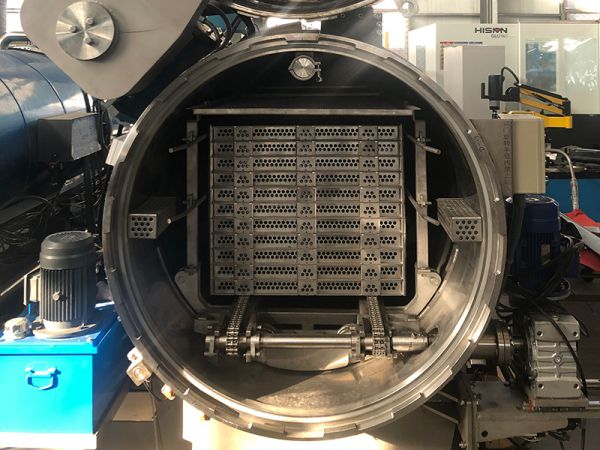

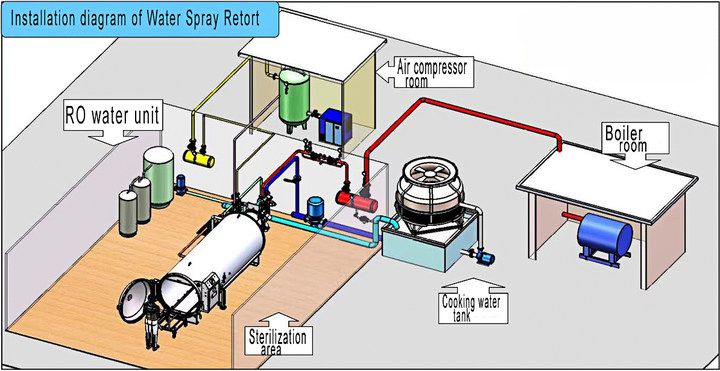

Sumpot water spray retort is designed to efficiently sterilize food products packaged in various containers. It adopts our independently developed fully-welded plate heat exchanger that features all-welded construction of heat-transfer plates and protective outer shell of pressure vessel, providing reliable durability, compact structure, efficient heat transfer, excellent resistance to high temperature and high pressure, and minimal fouling. Safety interlocking system and double safety valves are equipped to ensure safe conditions during the sterilization process.

The water spray retort is suitable for a variety of packaging containers, such as heat-resistant packaging, gas-contained packaging and flexible packaging.

- Glass containers: glass jars

- Metal containers: tinplate cans, aluminum cans

- Plastic containers: PP bottles, HDPE bottles

- Soft bag packaging: aluminum foil bags, transparent bags, vacuum bags

- Vacuum bags for cooking, etc.

This water spray retort controls the temperature and pressure gradually, ensuring uniform temperature distribution and stable pressure throughout the vessel which translate to consistent sterilization effect, thereby minimizing the package deformation and damage rate while maintaining the package integrity. High-level of automation enables the batch retort easy to operate and less labor intensity.

Multiple spraying methods are selectable to accommodate different packaging types such as flexible packagings, rigid containers, plastic bottles, and glass containers.

-

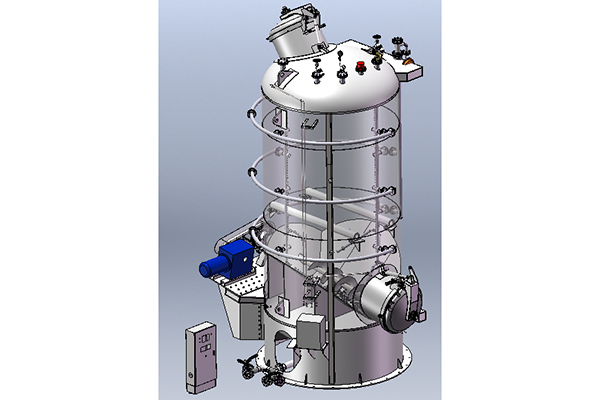

- Water Spray Retort with Preheat Tank If the product a customer is filling requires a temperature of at least 60 degrees, they should consider using a sterilization retort with a preheat tank. This will ensure the product is heated to the desired temperature.View More

-

- Water Spray Retort with Preheat Tank (with Electric Heating)Water spray retort with preheat tank is suitable for situations where the steam is not available, utilizing electric heating as a substitute for steam heating.

Water Injection: Fill the preheat tank with an appropriate amount of sterilized water and activate the electric heating tube to preheat the water to the set temperature.View More

-

- Water Spray Retort without Preheat TankIf the customer's product has an initial temperature near room temperature, a water spray retort without a preheating tank is recommended. This type of retort requires no additional tank, thus providing the added benefit of lower transportation costs and saving on sea freight due to its reduced size.View More

| Model | Dimension (mm) | Retort wall thickness (mm) | Max. working pressure (Mpa) | Max. working temperature (℃) | Approx. retort weight (kg) | Approx. operating weight (kg) | Power (kW) | Voltage (V) | ||||

| Capacity (m3) | ||||||||||||

| L | W | H | Top spray (water cascading) | Side spray / combined top and side spray | ||||||||

PLJ09-2 | 3080 | 1400 | 1400 | 4 | 0.3 | 130 | 1020 | 1500 | 1.33 | 3 | 4 | 380 |

PLJ10-1 | 2300 | 1500 | 1650 | 4 | 0.3 | 130 | 1000 | 1300 | 0.95 | 1.5 | 2.2 | 380 |

PLJ10-2 | 3100 | 1470 | 1650 | 4 | 0.3 | 130 | 1300 | 1800 | 1.65 | 3 | 5.5 | 380 |

PLJ12-2 | 3400 | 1700 | 1850 | 5 | 0.3 | 130 | 1380 | 2100 | 2.43 | 4 | 7.5 | 380 |

PLJ12-3 | 4300 | 1700 | 1850 | 5 | 0.3 | 130 | 1630 | 2750 | 3.46 | 4 | 7.5 | 380 |

PLJ12-4 | 5200 | 1700 | 1850 | 5 | 0.3 | 130 | 1860 | 3300 | 4.46 | 5.5 | 7.5 | 380 |

PLJ13-4 | 4600 | 1800 | 2100 | 6 | 0.3 | 130 | 2300 | 4000 | 5.81 | 7.5 | 11 | 380 |

PLJ14-4 | 5500 | 1900 | 2200 | 6 | 0.3 | 130 | 2500 | 4460 | 6.77 | 7.5 | 11 | 380 |

PLJ15-4 | 5800 | 2000 | 2400 | 6 | 0.3 | 130 | 2900 | 5900 | 7.82 | 11 | 15 | 380 |

PLJ15-5 | 6850 | 2000 | 2400 | 6 | 0.3 | 130 | 3250 | 6000 | 9.59 | 11 | 15 | 380 |

PLJ15-6 | 7700 | 2000 | 2400 | 6 | 0.3 | 130 | 3500 | 6700 | 11.35 | 11 | 15 | 380 |

- Standardized sterilization effect

The sterilization process is perfectly controlled and maintained with uniform temperature distribution and stable pressure control to accommodate various food processing methods, ensuring consistent sterilization effect thereby minimizing the package deformation and damage rate while maintaining the package integrity. - High safety

This water spray retort is equipped with fivefold safety interlocking system. Pressure vessel flange coupled with pressure relief valves can prevent safety accidents caused by violent opening of the door. Starting conditions are identified by detection system to eliminate safety issues due to human error. A safety alarm will be activated when any fault is detected during the sterilization process, allowing operators to solve the fault in a timely manner. - High-level of automation, cutting-edge configuration

This batch retort is highly automated for easy operation and less labor intensity. All critical parts are from world's renowned brands to provide smooth operation, superior look and stable performance. - Newly developed plate heat exchanger

All-welded construction of heat-transfer plates and protective outer shell of pressure vessel enables the plate heat exchanger capable of enduring high temperature and high pressure and achieving high heat transfer efficiency. Since it has no rubber gaskets for sealing, so that there are no worries about gasket aging. This fully-welded plate heat exchanger is also featured by reliable durability, compact structure and minimal fouling. - Ergonomic design

Our new generation autoclave control panel is configured with German Siemens touch screen that is placed at location allowing for easy operation and observation. Besides, operating status of the water spray retort is clearly showed in a form of animation via the touch screen, providing the entire process at a glance and enabling operator to easily control the system. - Premium quality, detail-oriented manufacturing

Our water spray retort features good insulating capability due to its outer shell covered with a 5cm thick layer of lightweight insulation material that has low thermal conductivity, preventing heat loss while maintaining high temperature uniformity and stability inside the vessel. This greatly saves energy consumption and enhances operation safety.

This batch sterilizer is a high-performance food processing equipment, offering:

- A clear operational status view with a Siemens control screen from Germany.

- Enhanced energy efficiency with 5cm thick insulation material.

- Enhanced safety with a fivefold safety interlocking system.